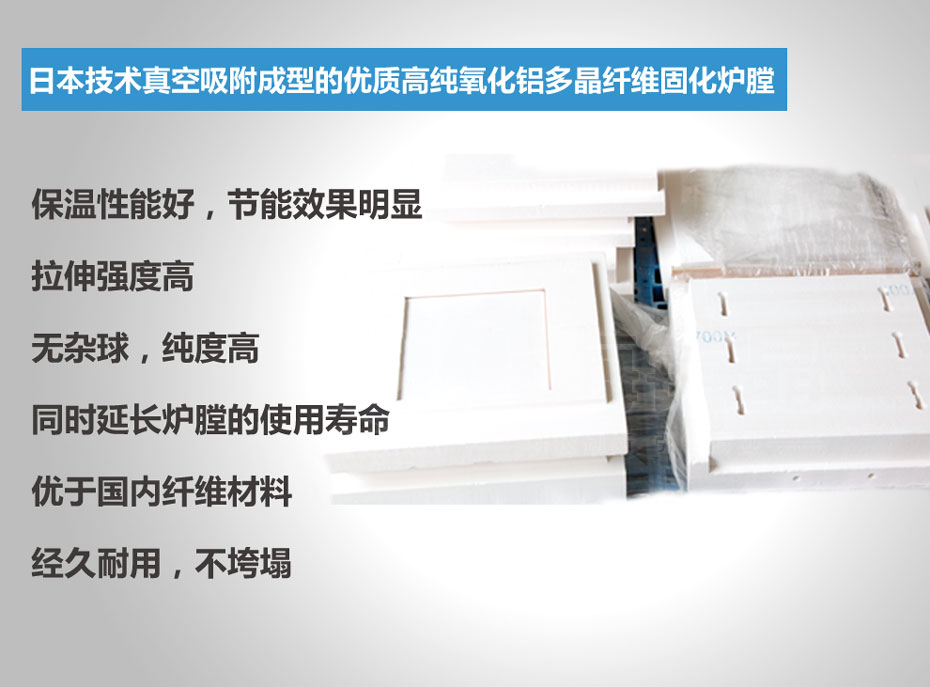

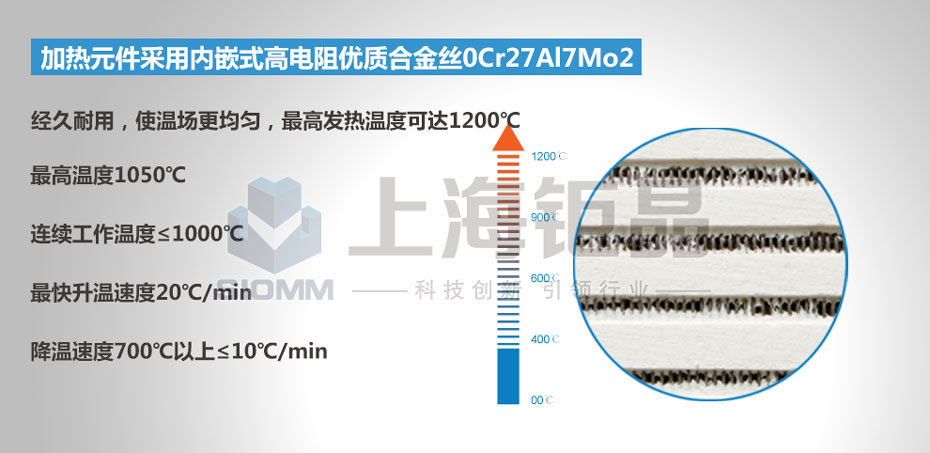

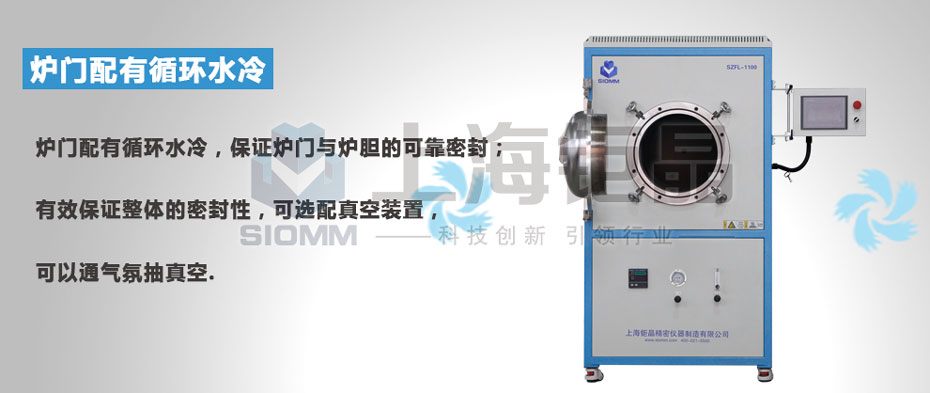

Main functions and features 1.Inner chamber is with temperature-resistance , pressure-resistance alloy material, can be vacuumized, vacuum up to below 0.1Pa, and can access a variety of protective atmosphere. 2.Chamber adopted imported alumina polycrystalline fiber material, good insulation properties, durability, high tensile strength, no miscellaneous ball, high purity, energy saving effect is better than the domestic fiber materials. 3.Heating element using embedded high-resistance high-quality alloy wire 0Cr27Al7Mo2, durable, the maximum heat up to 1200 ℃. 4.Furnace door use circulating water cooling system, which can effectively ensure the overall sealing. 5.Visual 7-inch touch screen, setting the data and operation are graphic interface, easy to operate. 6.Can preset a number of heating curves, assigned to different sintering materials.When necessary, direct calls, do not interfere with each other, without repeating the modified temperature parameters. 7.Rotatable touch screen structure, strong operation. 8.Configuration import pressure sensor, overpressure automatic pressure relief protection, safe and reliable operation. 9.Reserved 485 conversion interface, through our special software, and computer interconnection, can achieve a single or more electric furnace remote control, real-time tracking, historical records, output statements and other functions. 10.Over- heat alarm and power off, leakage protection, safe andreliable operation. |