This furnace is a powerful heating equipment developed by our company independently. It mainly used in denture sintering industry (dental zirconia sintering), also can be used in powder metallurgy industry which require the furnace can do high-temperature sintering / anneal with protective gas. Equipped with imported silicon molybdenum rods, working table automatic lifting and down, decent appearance, scientific and reasonable structure, this furnace is a mainstream product in the field of high temperature sintering equipment.

Main functions and features:

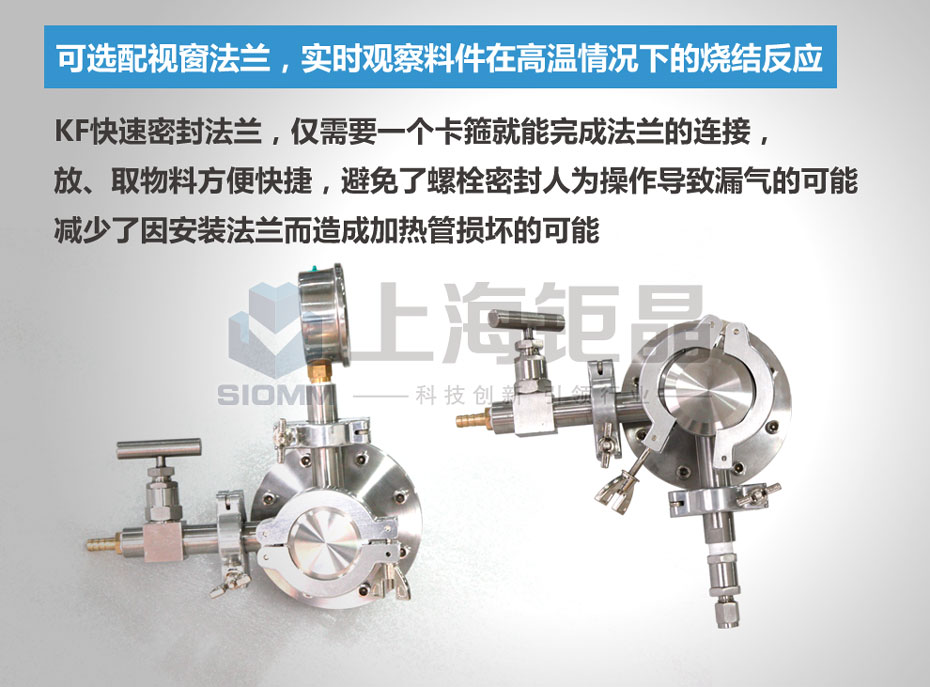

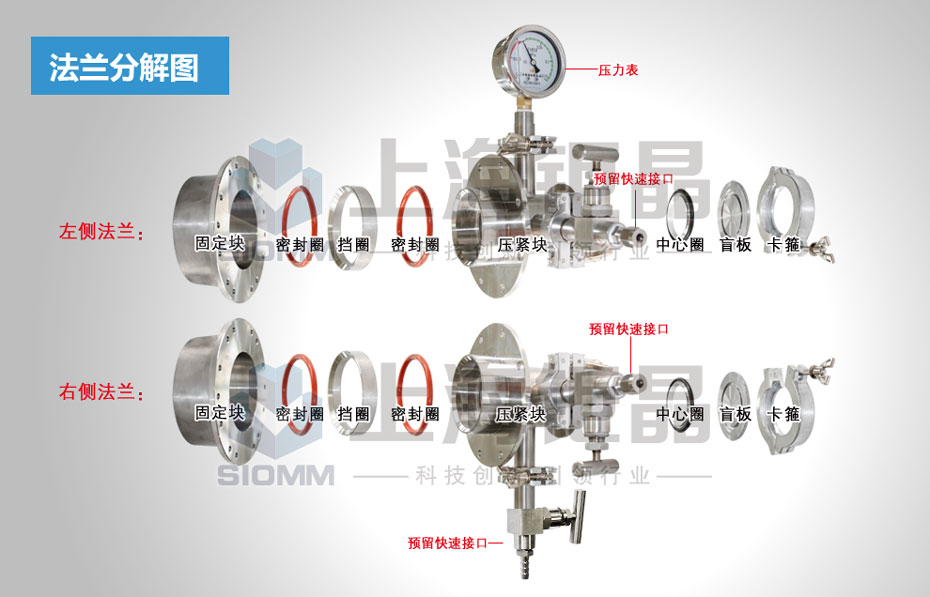

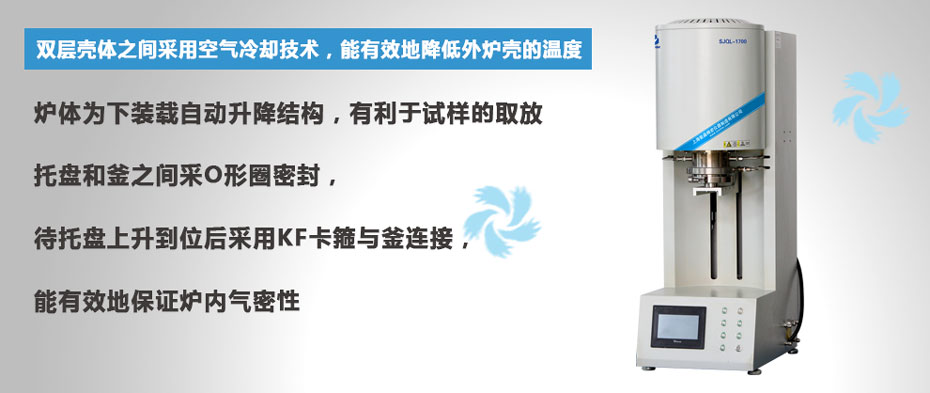

1. With automatic lifting and down working table, this furnace is very convenient to put and take specimen; The working table and heating reaction vessel was sealed by ‘O-ring’ , and when the working table rise to the working position will use the KF flange to connect with heating reaction vessel, effectively ensure the air impermeability of the furnace.

2. The furnace with double-shell structure and between the shell equipped with air cooling system, ensure the furnace surface have a low temperature, operation more safety.

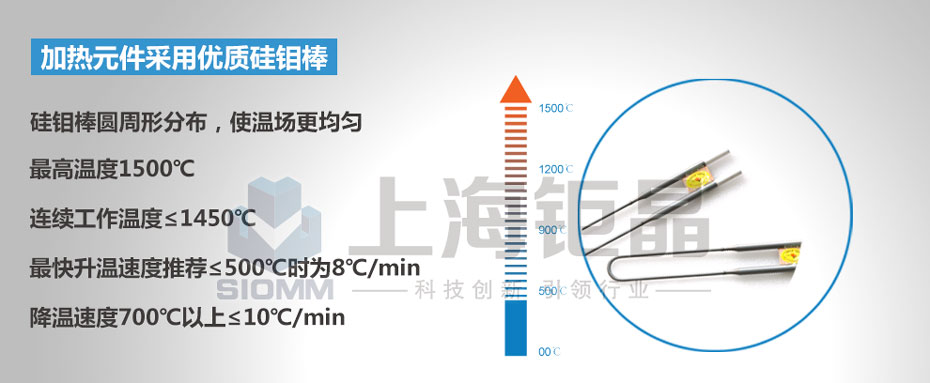

3. Adopts cylindrical structure, heating element is uniformly distributed on the circumference of a circle, the furnace temperature field uniformity is very good.

4. Reserved vacuum, gas road fast connection interface, could working with our vacuum system or mixed gas system.

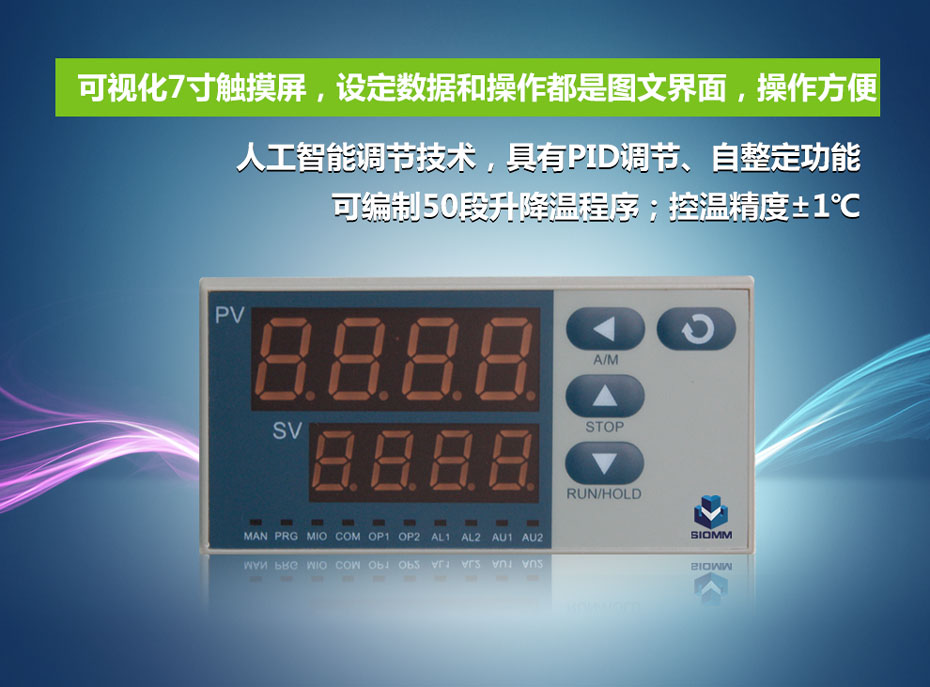

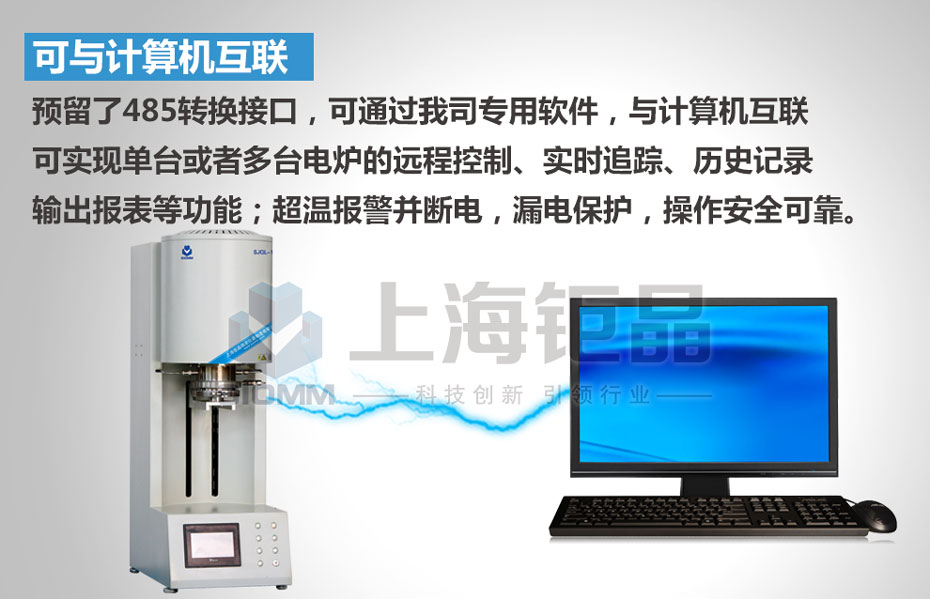

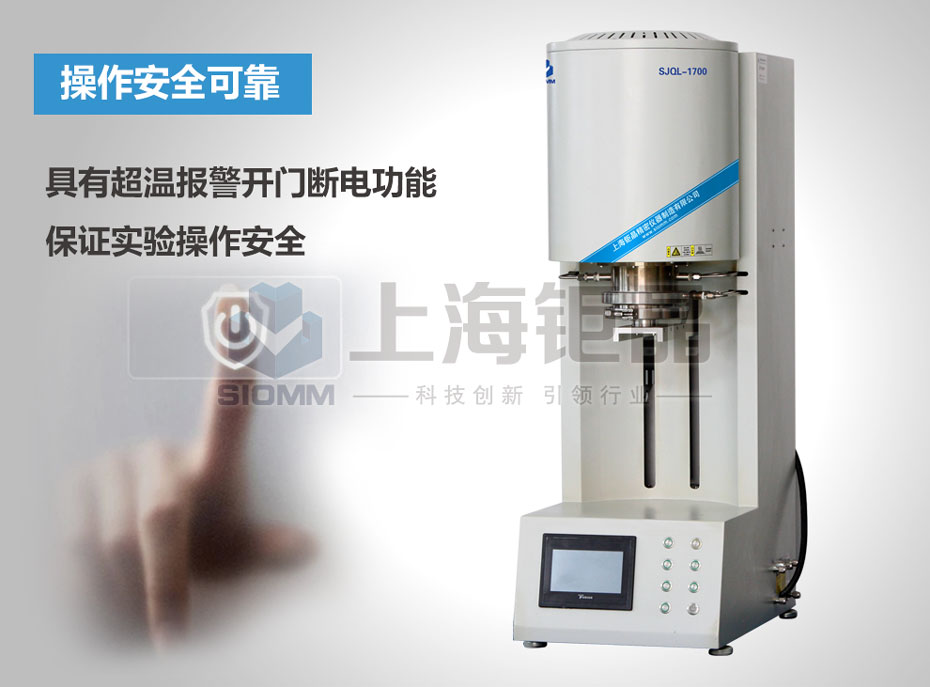

5. With touch screen control system, this furnace very easy operation; Connected with PC via our software, it can achieve remote control, real time tracking, history recorder, and output report function.

6. Over-temperature alarm, electric leakage protection, ensure safe and reliable operation.

Specification:

Model | SJQL-1700 |

Heating zone | Single heating zone |

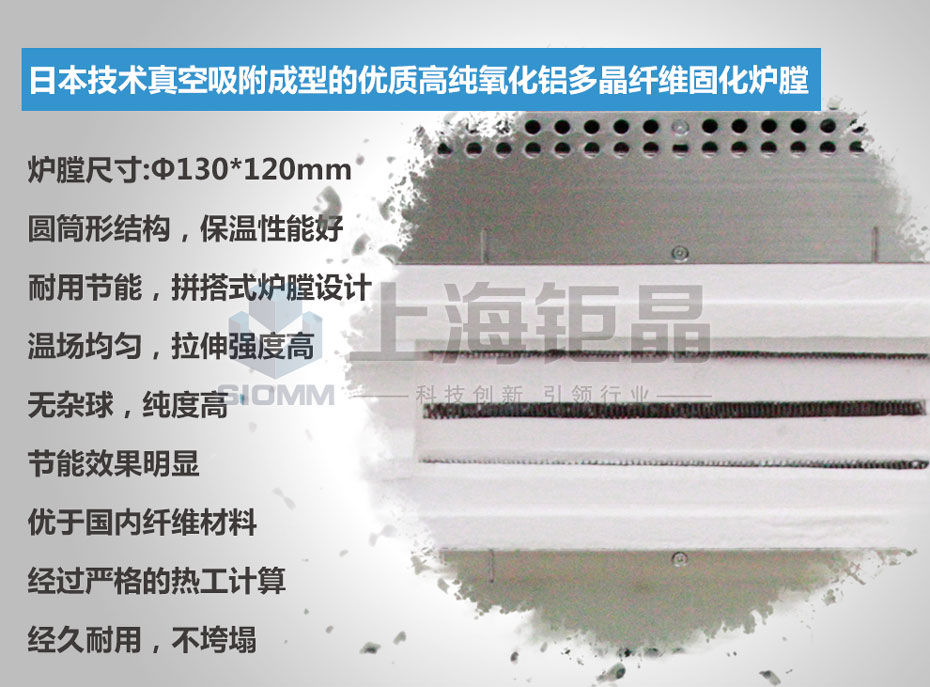

Heating zone height | 120mm |

Heating zone diameter | Φ130mm |

Rated power | 3KW |

Max. temperature | 1650℃ |

Continuous Working temperature | ≤1600℃ |

Furnace chamber | Imported high pure polycrystalline alumina fiber, excellent heat preservation |

Temperature control accuracy | ±1℃ |

Recommend heating rate | 10℃/min; Max 20℃/min |

Heating element | Imported silicon molybdenum rods |

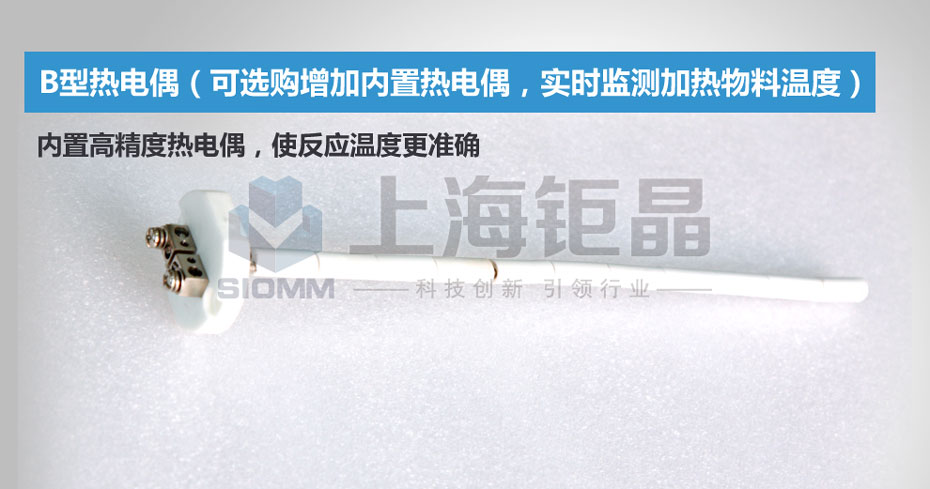

Thermocouple | B mode thermocouple |

Temperature control | Adopted artificial intelligence technology,With PID control, self - tuning function, 30 segments heating and cooling program |

Sealing type | Stainless steel flange extrusion seal |

Working power | AC220V 50HZ/60HZ |

Standard accessories | “O”rings 2pcs laboratory tray 3pcs oven gloves 1pc crucible tongs 1 pc |

Weight | About 150kg |

Overall size | 650×450×1300(L*W*H) |