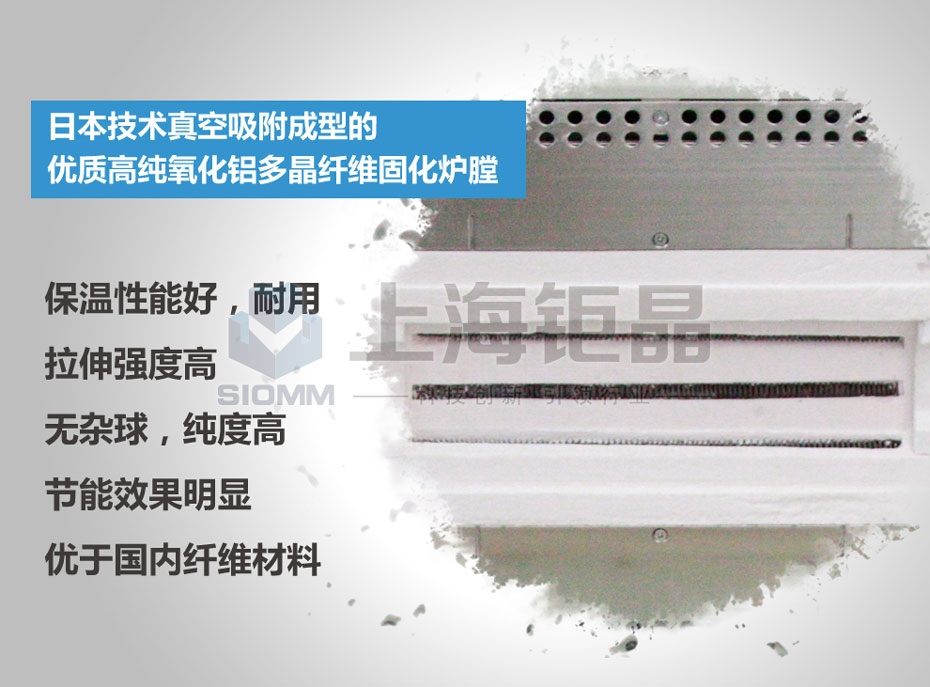

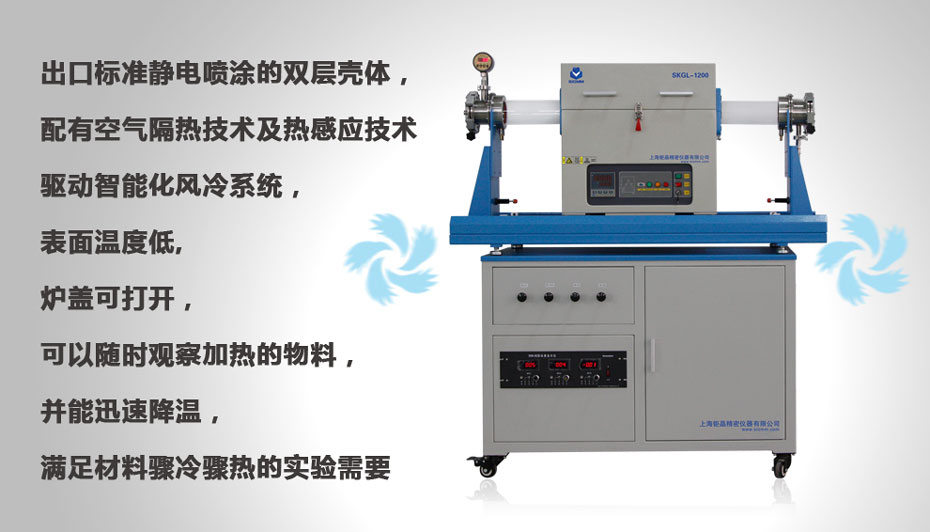

furnace body construction | Equipped with cooling fan between double shell, ensure low temperature of furnace surface. Furnace chamber use high quality polycrystalline alumina fiber, good heating preservation and more durable; At the bottom of the furnace is equipped with slide rail, moving smoothly; Furnace can slip from one side to another side by manual operation, achieve rapid heating and cooling Inner side of the support installed the oil buffer Open type furnace can real-time observe heating status of materials |

Power source | Voltage: AC220V 50/60Hz; Power: 4KW |

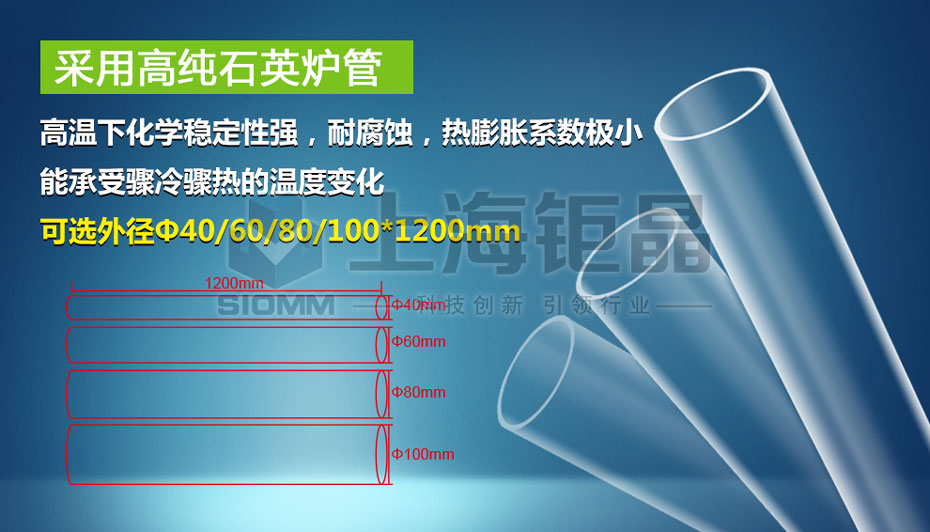

Furnace Tube | High purity quartz tube, strong chemical stability under high temperature, corrosion resistance, small thermal expansion coefficient Size: Φ40/60/80/100*1200mm |

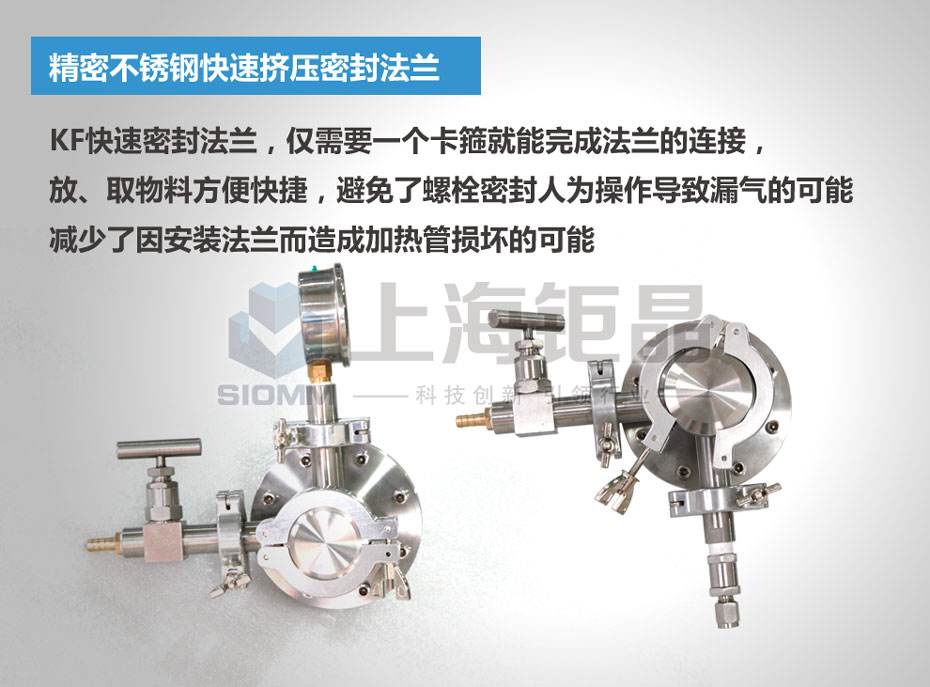

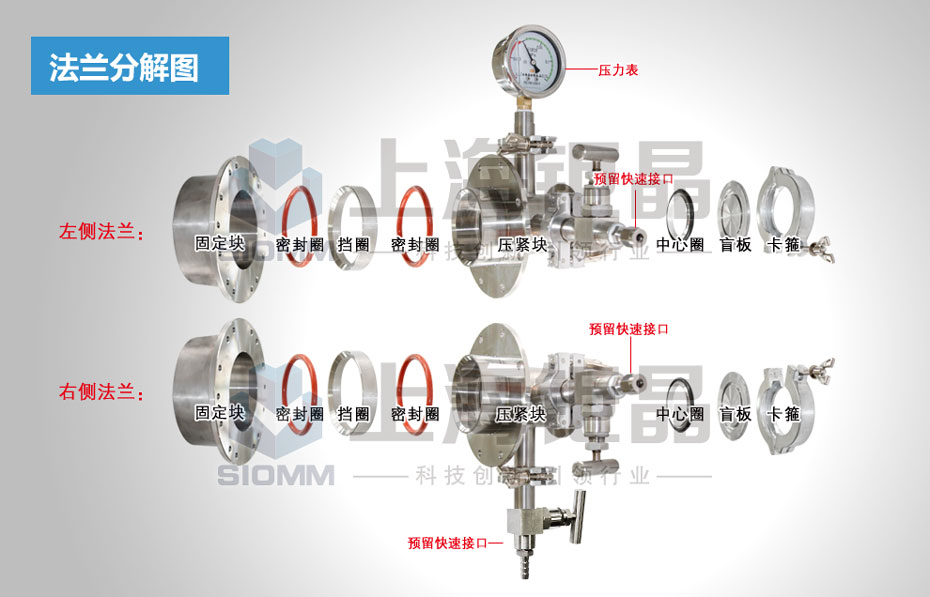

Flange and support | SUS304 stainless steel flange, using high temperature resistant "O" ring tight seal the flange can obtain high vacuum degree; Adopted KF quick flange sealing, only need a clamp flange the connection can be done. It is very convenient to put and take the specimen. Adjustable flange support, it can balance the stress of the furnace tube support Including Air inlet, air outlet, vacuum outlet valve, KF seal ring and flange clamp combination |

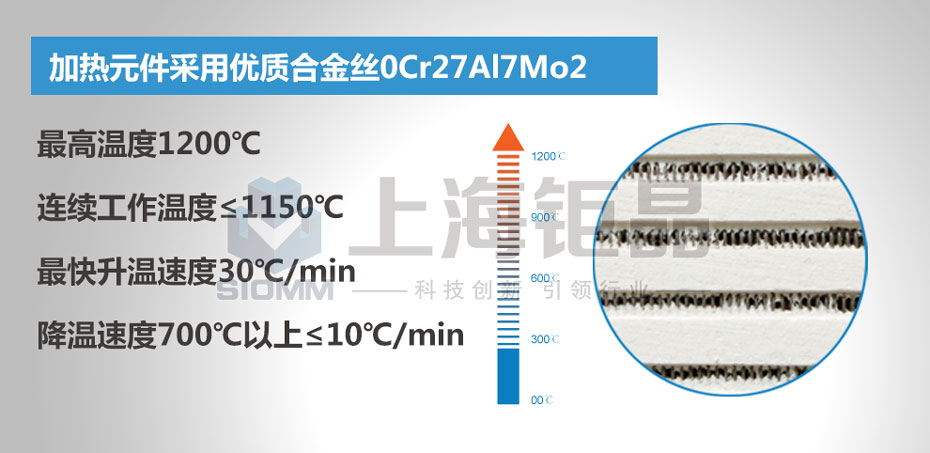

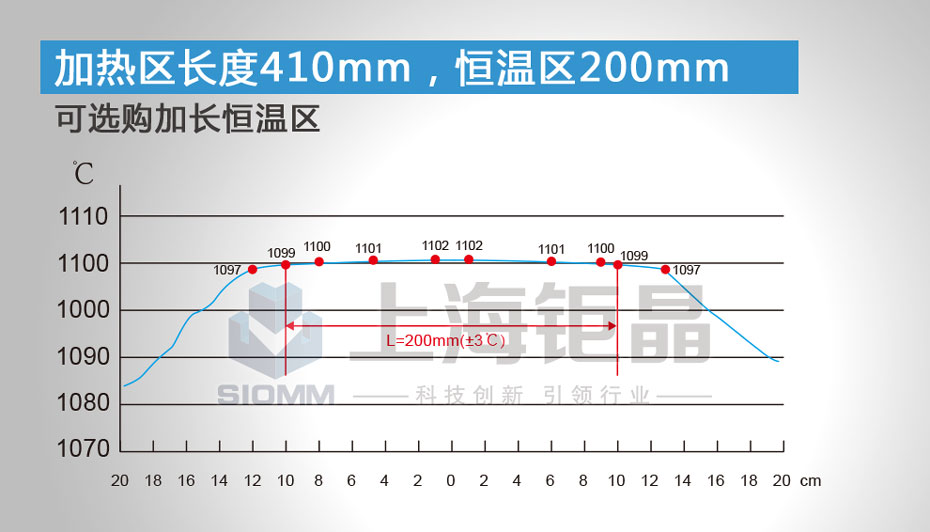

Heating system | Heating element adopted high quality alloy wire 0Cr27Al7Mo2, high surface load, servicing time more longer; Heating zone length: 410mm Constant temperature zone length: 200mm Working temperature: ≤1150℃ Max. Temperature: 1200℃ Heating rate: 10℃/min |

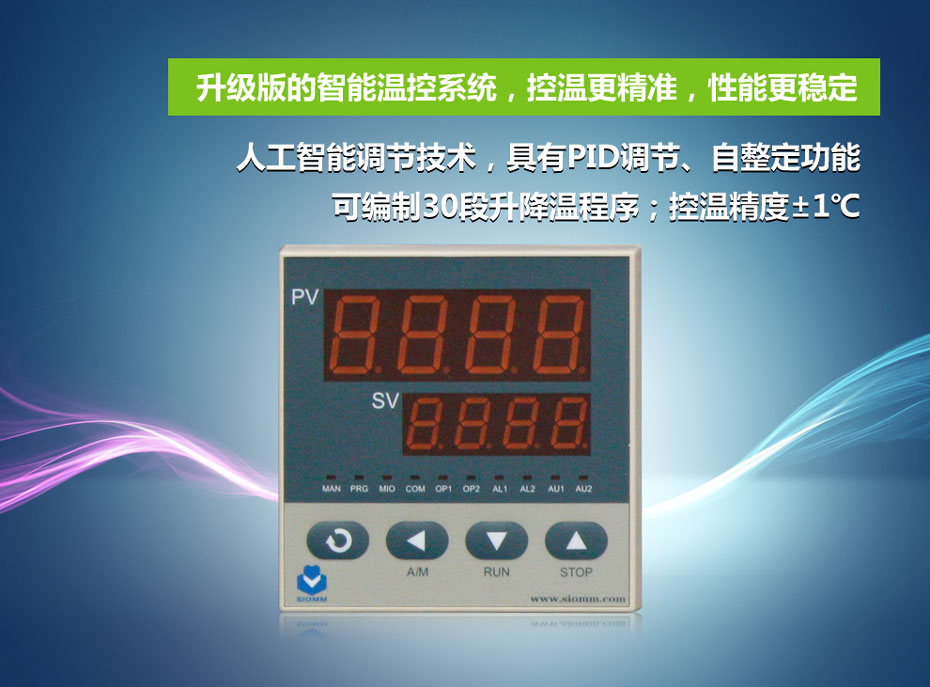

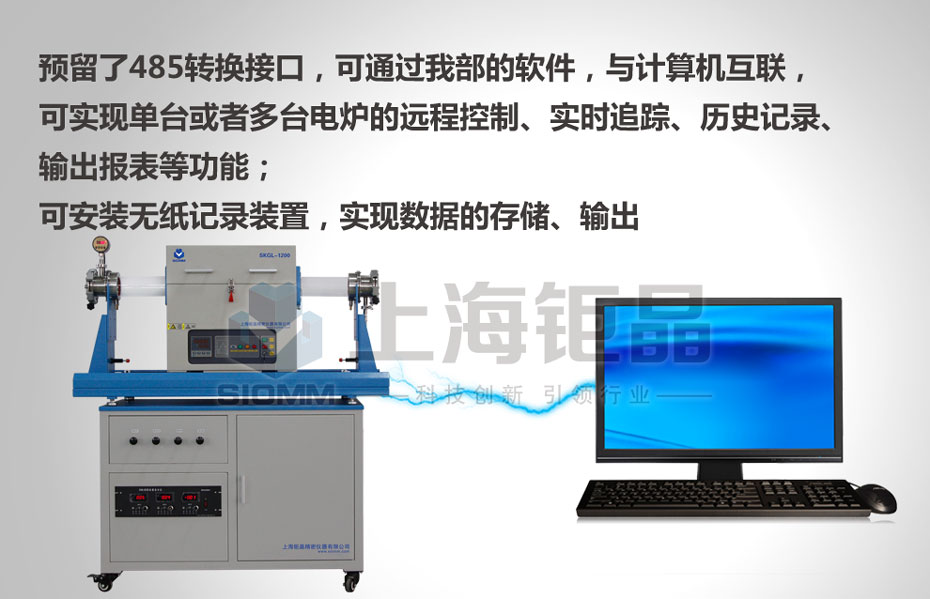

Temperature control system | The temperature control system uses artificial intelligence technology, with PID control, self - tuning function, 30 segment heating and cooling program; Thermocouple: N mode thermocouple Precision of constant temperature: ±1℃ |

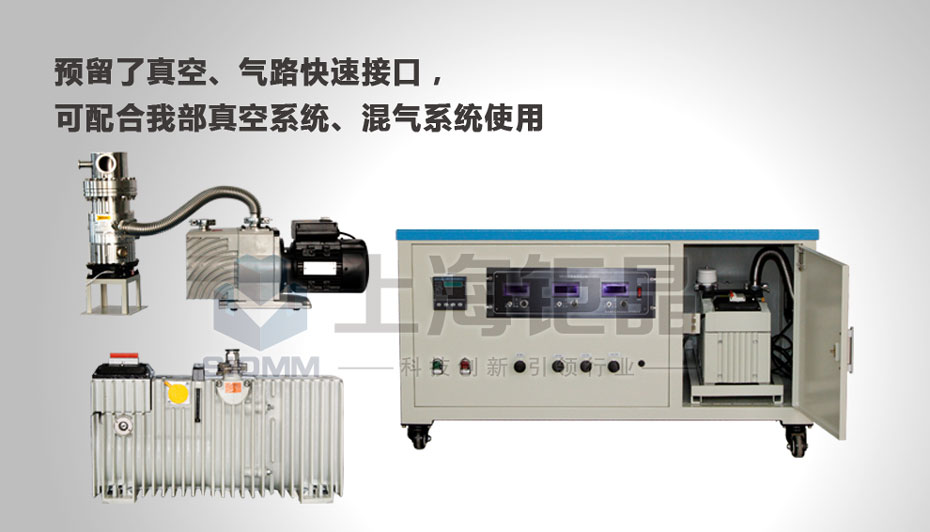

Mixing gas system | Three routes mass flow meter: digital display, automatic control the gas flow rate; Internally installed stainless steel gas mixing tank, every route gas equipped with check valve; Gas route use stainless steel pipe, connect by Φ6 cam lock Each gas inlet line equipped with stainless steel needle valve Rotate the button on operation panel can adjust the gas flow rate Flow range: 0~1SLM Flow accuracy: ±0.5% |

Vacuum system | Two stage rotary vane vacuum pump, vacuum degree can reach 5x10-1 Torr (If need more higher vacuum degree can choose our molecular pump system and pressure control system) Digital display vacuum pressure meter |

Standard configuration | Furnace 1 set; Seal flange 1 pc; O-ring 4 pcs Quartz tube 1 pc; Casing cap 4 pcs; Crucible hook 1 pc Manual book 1 pc; Quality certificate 1 pc; Warranty card 1 pc |

Optional accessories | Mixing gas system, Low, medium and high vacuum system; All kinds of alumina crucibles; Quartz tube; Computer control software; Paperless recorder, Oxygen analyzer, etc. |