Multifunction digital Rockwell hardness tester has high level automation, stable and reliable performance, it is equipped with sophisticated sensors so that can test data more accurate ;

5.6 inch digital LCD screen provide comprehensive data for quality control.

Main function and features:

1. Equip with sophisticated sensors, more accurate test results, leading load structure design, can easily switch test force;

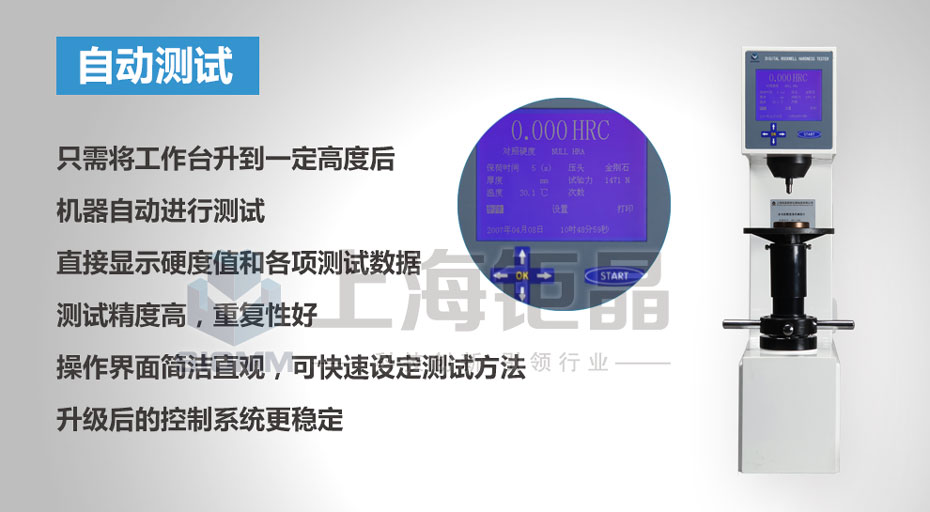

2. It is automatic to test when the workbench lift up to certain height, then indicate the hardness value and test data directly;

3. With Chinese and English operation interface, can be set in test method quickly, the upgraded control system is more stable;

4. Indicate the hardness value, hardness unit, conversion hardness, test force, indenter type, minimum thickness, dwell time, test number, test process on the LCD screen directly; Built-in printer, it can print out the test data directly;built-in printer can print the measure count, hardness value, average value, maximum and minimum values, range data for our customer;

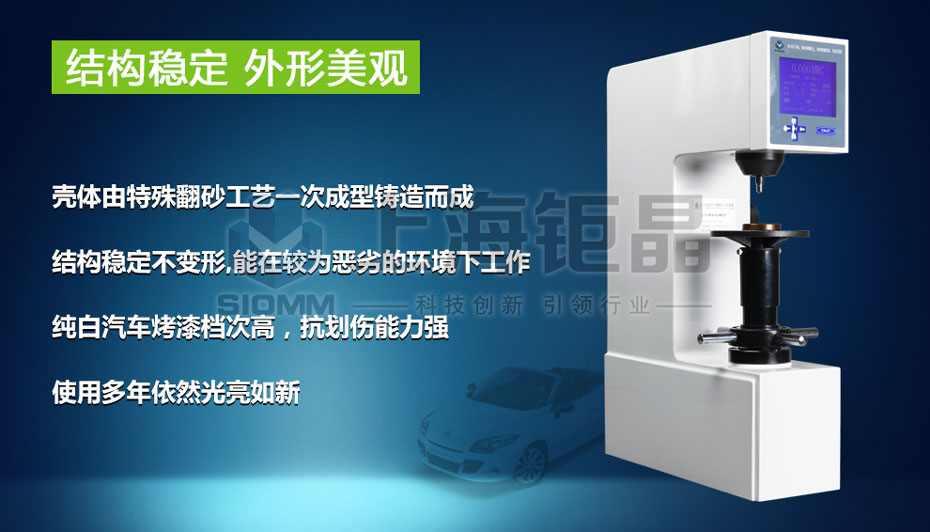

5. One-time casted molding shell, stable structure and it is not easy to be out of shape. It can work under harsh environment; the shell coating adopted car paint technology with white color. it has strong scratch resistance capability and still look bright as new after use many years;

6. Factory directly supply, we have products develop &design & produce ability, all the parts provide life-time replacement and maintenance service;

Main Application:

Hardened steel, quenched and tempered steel, annealing steel, bearing steel, strip steel, hardened steel sheet, hard alloy, etc.;

Technical parameter:

Model | HRS-150D ( CE certificate, Certificate number: GB / 1067/3980/12 Issue 1) |

Rockwell scale | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR |

Conversion scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, H15N, H30N, H45N, H15T, H30T, H45T |

Preliminary test force | 10Kg(98.0N) |

Total test force | 60Kg (588N), 100Kg (980N), 150Kg (1471N) Tolerance range:±1.0% |

LCD screen size | 118x99mm |

Resolution | 0.1HR |

Hardness value range | HRA:20~88 HRB:20~100 HRC:20~70 |

Hardness data read | Digital LCD screen |

Loading method | Automatic (Load, Dwell ,Unload) |

Dwell time | 1~99S, each step: 1 second |

Allowed specimen measurement space | Maximum height :170mm Maximum throat depth:130mm (There is another heightened type, which is allowed maximum height 400mm) |

Size / weight | Instrument size:460*160*660mm (L×W×H) / Net Weight: 85kg Packing size: 625*430*900mm (L×W×H) / Gross Weight: 95kg |

Power supply | AC220V + 5%, 50~60 Hz; (can change to 110V) |

Data output | Built-in printer |

Executive standard | GB/T230.2, ASTM E18, ISO 6508, JJG112 |

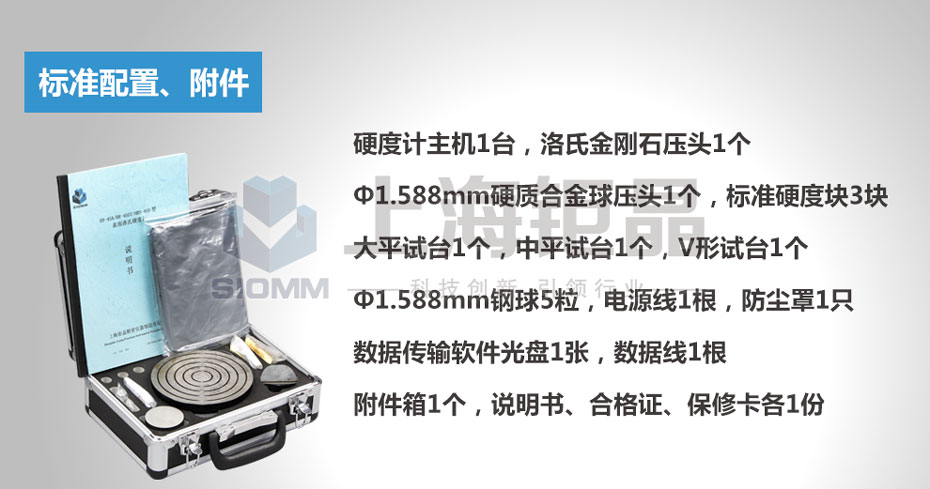

Standard accessories | Rockwell hardness tester host: 1 set Diamond Rockwell indenter: 1 pc 1.588mm diameter hard alloy steel ball indenter: 1 pc, Standard hardness block: 3pcs Large testing table: 1 pc Medium testing table: 1 pc V-shaped testing table: 1 pc, 1.588 mm diameter steel ball : 5 pcs Power cable: 1 pc , Dust-proof cover: 1 pc, Accessory case : 1 pc Operating instruction : 1pc Quality certificate : 1 pc Warranty card : 1 pc. |

Optional accessories | Block, Indenter |