Multi-function digital display universal hardness tester have high degree of automation, stable and reliable performance, equipped with sophisticated sensors, test is more accurate; A 5.6 inch industry screen provide comprehensive data for quality control, through hardness transmission software export test data into the computer conveniently, easy to long term preservation.

Main function and features:

1. Can meet Rockwell and small load Brinell and Vickers hardness test requirements, it’s convenient for user to do a variety of materials at the same time.

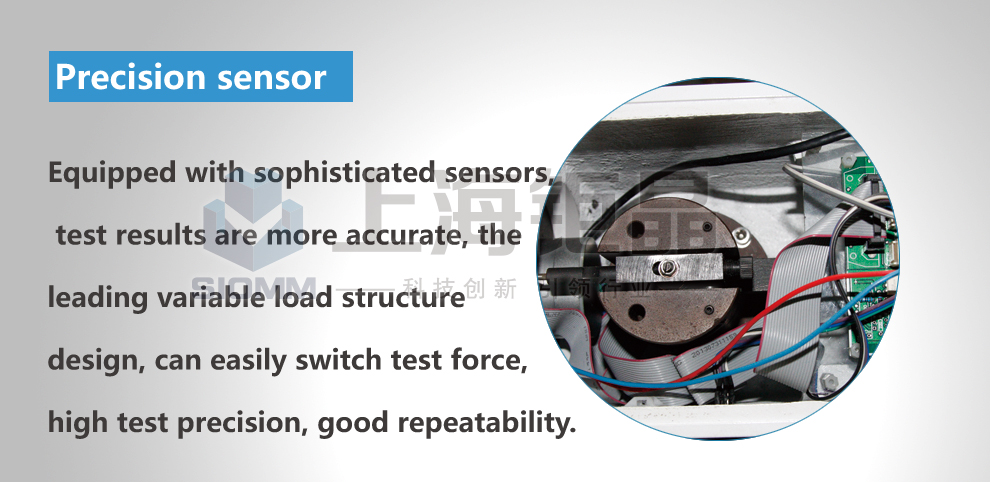

2. Equipped with sophisticated sensors, test results are more accurate, the leading variable load structure design, can easily switch test force, high test precision, good repeatability.

3. The main components adopt brand such as American 3M, Allegro, Japan Omron and NKK, to ensure the equipment running stably for a long time.

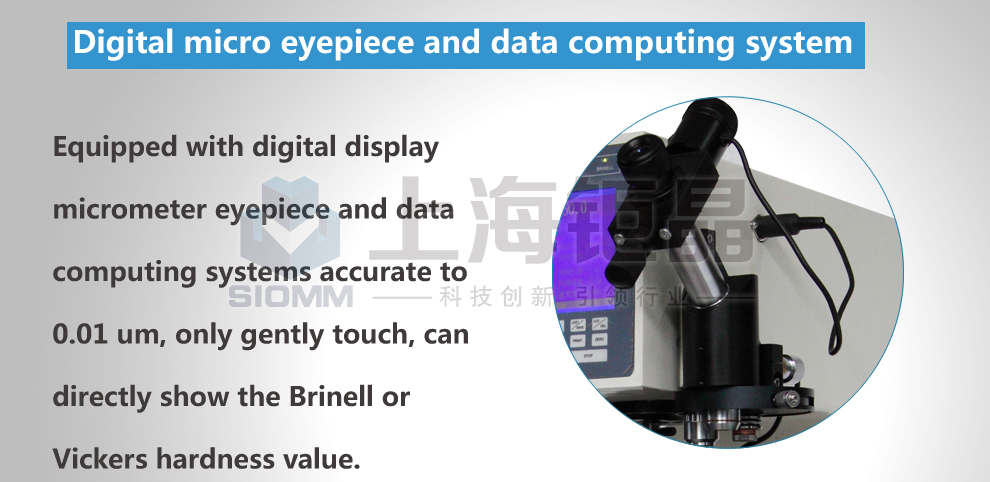

4. Equipped with digital display micrometer eyepiece and data computing systems accurate to 0.01 um, only gently touch, can directly show the Brinell or Vickers hardness value.

5. It is automatic to test when the working platform lifting up to some height, then indicate Rockwell hardness value and various testing data directly.

6. Both Chinese and English operation interface are simple and intuitive, can set the test method quickly, the control system is more stable after upgraded.

7. The industry LCD screen can be visual display hardness value, hardness unit, conversion hardness, testing force, indenter type, the required minimum thickness, load time, measurement times, and the test process is intuitive and clear, built-in printer can print out measured times, hardness value, average, maximum and minimum values, range for the customer to archive.

8. Accompanying equipped with data transfer software, through RS232 interface will transfer

host measurement data to the computer to edit and save.

9. The shell is one step casting molding with special foundry process, stable structure and no deformation, can work under relatively harsh environment; Pure white car painting and its class is high, have scratch resistance ability, it’s still brightness used for years.

10. We have our own research and development design, production and processing ability, our machines provide life-long time parts replacement and maintenance upgrade services.

Main Uses:

1. Chilled steel, quenched and tempered steel, annealing steel, bearing steel, strip steel, hardened steel sheet, hard alloy, etc.

2. Cast iron, nonferrous metal, especially for soft metal, such as pure aluminum, lead, tin, etc.

3. Carburizing, nitriding and decarburization layer, the surface hardening layer, electric plating and coating.

Technical parameters:

Model | HBRVD-187.5 (Approved by CE certificate, ensure the safety operation of the machine. Certificate No.: GB/1067/3980/12 Issue 1) |

Rockwell scale Test force | HRA, HRB, HRC,HRD,HRE,HRF,HRG,HRH,HRK,HRL,HRM,HRR 60Kg (588N),100Kg (980N),150Kg(1471N) |

Brinell scale Test force | HBW2.5/31.25,HBW2.5/62.5,HBW5/62.5, HBW2.5/187.5 31.25Kg(306.5N),62.5Kg (612.9N), 187.5Kg (1839N) |

Vickers scale Test force | HV30,HV60,HV100 30Kg(294.2N),60kg(588N),100Kg (980N) |

Conversion Scale | HRA,HRB,HRC,HRD,HRF,HV,HK,HBW,HR15N,HR30N,HR45N,HR15T,HR30T,HR45T |

Initial test force | 10Kg(98.0N) |

LCD Screen size | 118x99mm |

Resolution ratio | 0.1HR |

Amplification of microscope | 37.5X, 75X |

Hardness value range | Rockwell: 20~88HRA 20~100HRB 20~70HRC Brinell: 8~650HB Vickers: 8~3000HV |

Hardness value read | Big digital LCD |

Loading method | Full automatic (load, dwell, unload) |

Specimen maximum height allowed | Rockwell: 170mm Brinell, Vickers: 140mm |

Throat depth allowed | 130mm |

Dwell time | 1~99S ( each step is 1 second) |

Power supply | AC220V + 5%, 50~60 Hz , (AC110V available) |

Instrument size and weight | 460×160×660mm (L×W×H), 85kg |

Package size and weight | 625x430x900mm (LXWXH), 100kg |

Data output | Built-in printer, RS-232 interface (Export data to the computer for long time preservation) |

Executive standard | GB/T230.2,GB/T231.2,GB/T4340.2,ASTM E18,ISO 6508,JJG112,JJG150,JIS B-7734 |

Standard accessories | 1 piece: Hardness tester ; 15x digital display micrometer eyepiece ; 2.5x , 5x object lens ; Rockwell diamond indenter ; Vickers diamond indenter ; Φ1.588mm,Φ2.5mm,Φ5mm, hard alloy ball indenter ; large, medium, “V” shape, and slide test platform ; data transmission software ; accessory box ; dust-proof cover ; power cable ; manual instruction; certificate of quality; warranty card . 5 pieces: Φ1.588mm steel ball ; hardness block . |

Optional accessories | Hardness measurement software, brand computer, printer, standard hardness block, standard indenter |