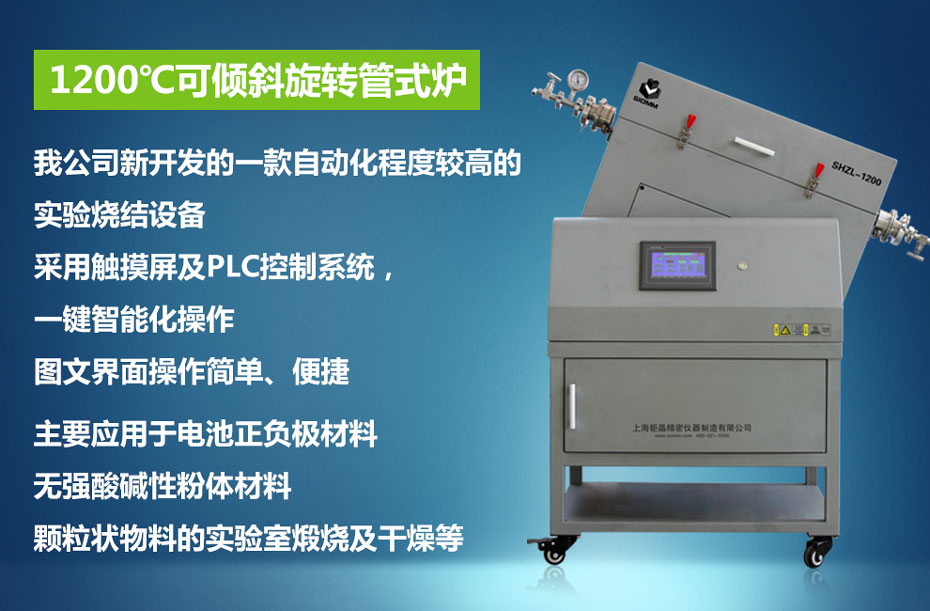

Products Introduce:

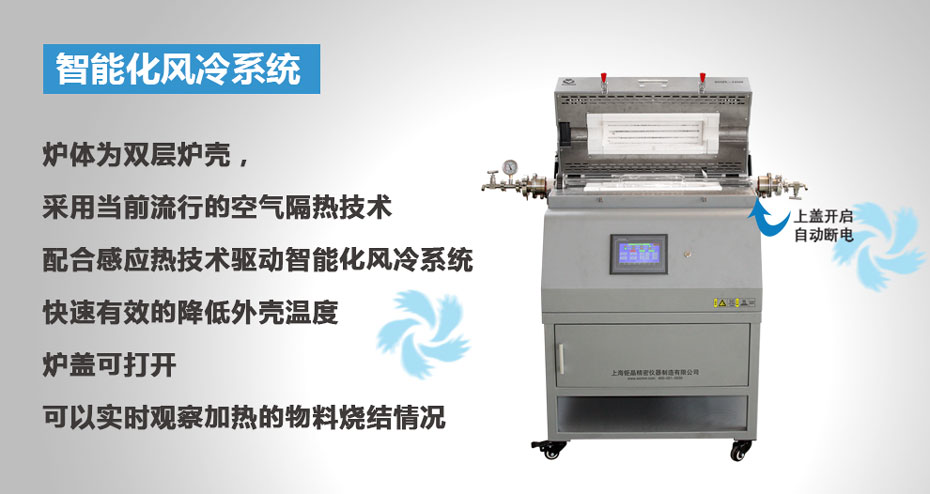

SHZL-1200 Tiltable rotary tube furnace is a lab sintering equipment which is a advanced products researched by us. Unique touch screen and PLC control system, just through one key can do intelligence operation; graphic interface easy for operation; furnace body can be tilted, furnace tube can be continuous rotary; And there have separation blade inside the tube, it can help stir the powder and ensure the sintering more uniformity; It can fast cooling through open the top lid.

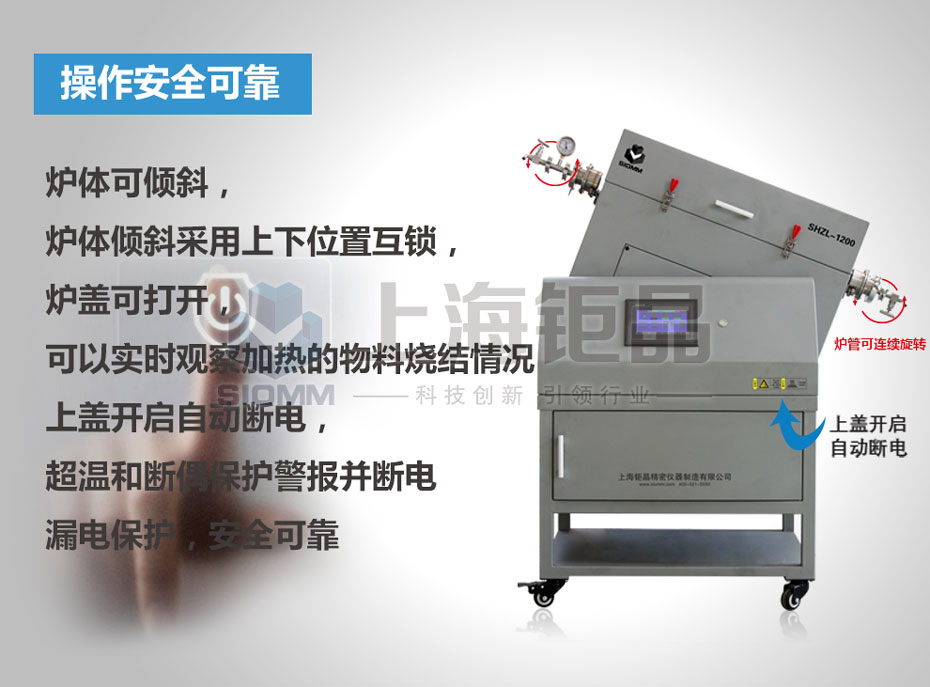

Function and feature:

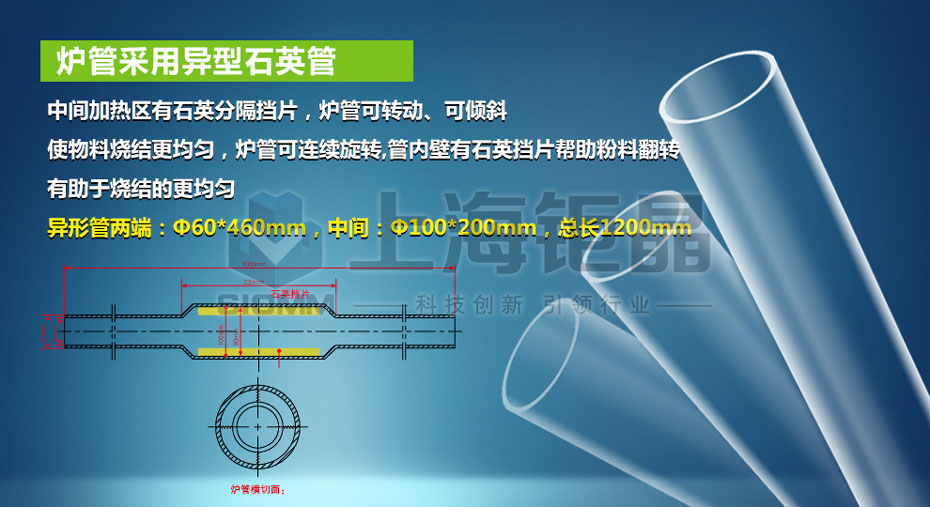

1. Adopted special-shaped quartz tube, there have a quartz material separating blade in the heating zone, tube can be rotary and tilted, ensure the sintering more uniformity.

2. Automatically, all functions can be setting through the digital screen, intuitive and easy operation;

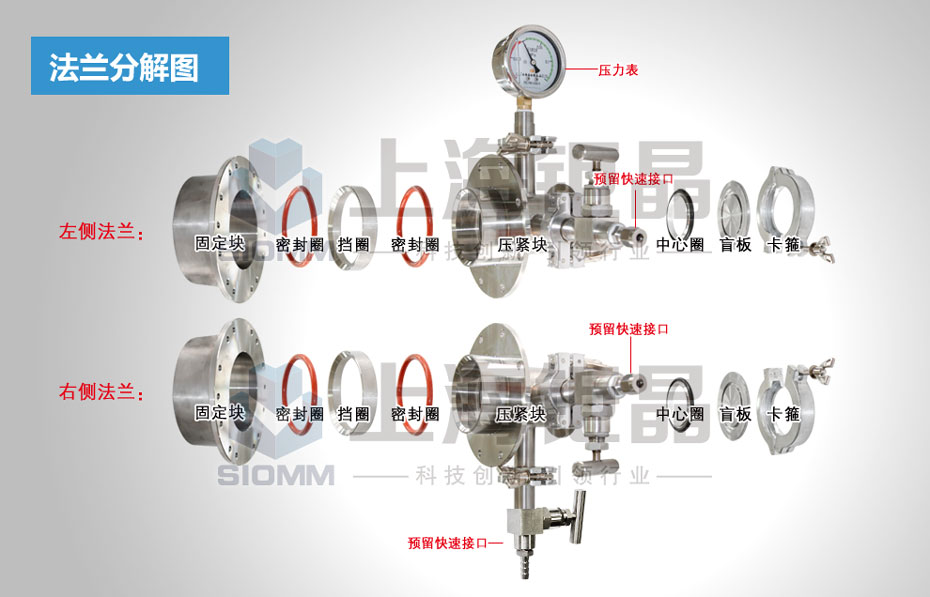

3. Using KF flange (sealing fast), easy to operate;

4. The lid can be opened to real-time observe the sintering conditions of heated material;

5. Reserved vacuum / gas fast connection interface, the furnace can be working with our vacuum system and mixing gas system.

Main applications:

Mainly used in the lab for calcination or drying battery anode material, no acid and alkaline powder materials, granular materials.

Specification:

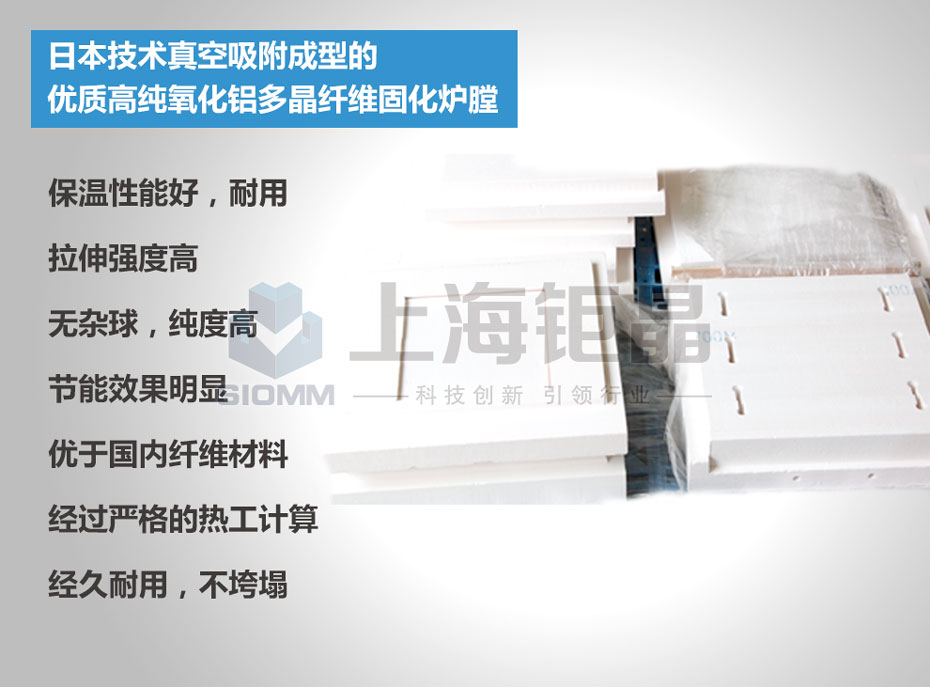

Furnace structure | Double shell with cooling system, ensure the low temperature of body surface; Furnace chamber adopted vacuum forming technology, use high-purity polycrystalline alumina fiber material, with more better insulation properties. Use noiseless DC motor to achieve tilt function; Open type furnace, real time observe the heating status of specimen, and cooling fast. |

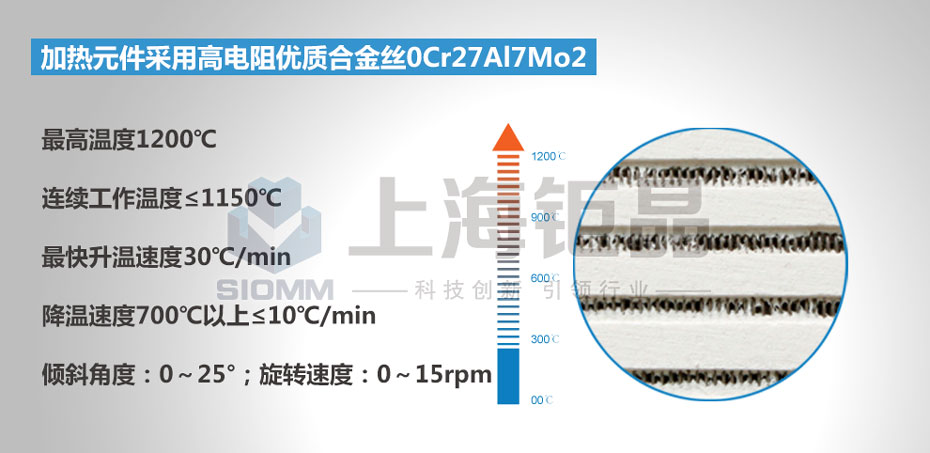

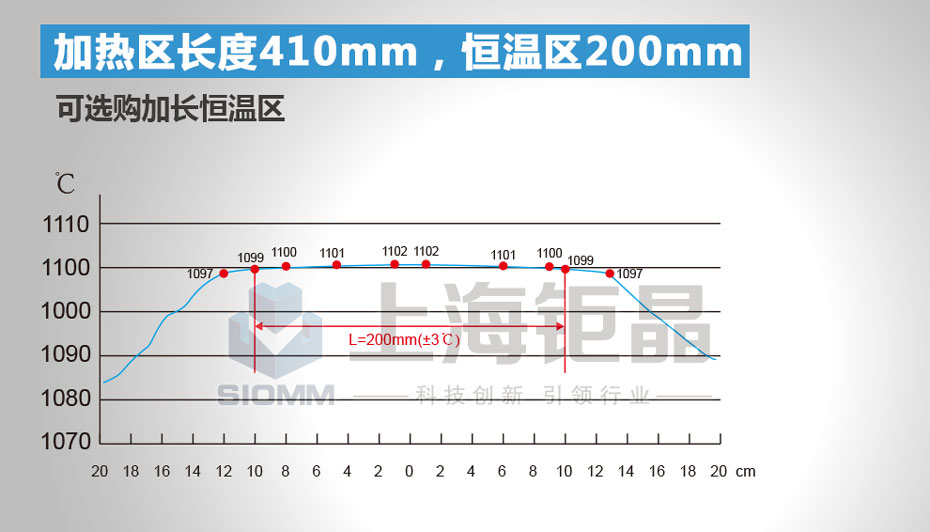

Heating system | Heating element use high quality alloy wire 0Cr27Al7Mo2, high surface load and long time service time. The length of heating zone: 440mm The length of constant heating zone: 200mm Working temperature: ≤1150℃ Max. Temperature: 1100℃ Heating rate: 10℃/min |

Furnace tube | High purity quartz tube, more chemical stability under high temperature, corrosion resistance, small coefficient of thermal expansion;

The both end size of tube: φ60*460mm, middle: φ100*280mm, total length: 1200mm; Four separating blade for stir the specimen, ensure sintering more uniformity when working in rotary status. |

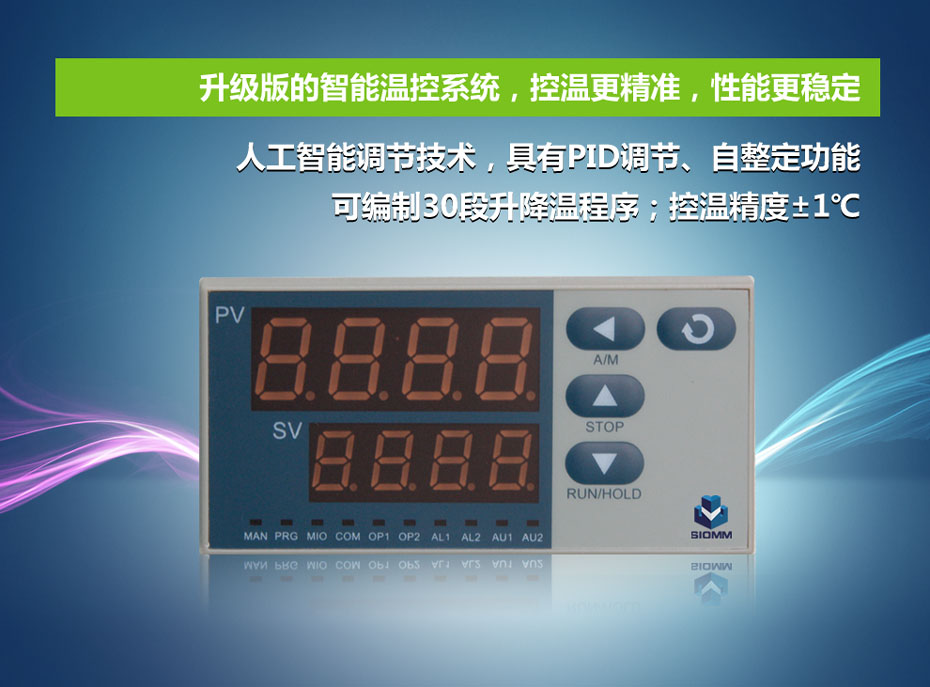

Temperature control system | Touch screen temperature control, with PID control, self-tuning function 30 segments heating and cooling program Temperature components: N-type thermocouple Temperature accuracy: ± 1 ℃ Heating rate: 10 ℃ / min |

Operation type | Touch screen intelligence control Tilt with up and down position limits, safe and reliable Rotation speed adjustable 0 ~ 15RPM The angle of inclination: 0 ~ 25° |

Working power | AC220V 50Hz/60Hz ,4kw |

Standard accessories | O-rings 4 pcs, special shaped quartz tube 1 pc, stainess steel flange 1 pc, oven glove 1 pc, crucible tongs 1 pc |

Weight | About 150KG |

Dim. | 850×670×1200mm

|