PECVD-1200 is consist of open type tubular furnace (OD60/80*1200mm), vacuum system, 500W RF plasma source, 3 channels precision mass flow meter with gas mixing tank, and high quality mechanical pump. The PECVD furnace is an ideal and affordable tool to deposit thin films or grow nano-wire from a gas vapor to a solid state. It offers a wide range of material deposition, including SiOx, SiNx, SiOxNy and Amorphous silicon (a-Si:H) deposition, etc.

Features:

1. This system with features of low basic temperature, fast deposition rate, high quality film, less pinholes, and not easy cracks, etc.

2. Working table with wheel, easy to move.

3. With high precision mass flow meter, can accuracy control the gas flow rate.

4. High quality mechanical pump with digital vacuum gauge, can reach to 0.1Pa. (molecular pump can reach to 0.001Pa)

Specification:

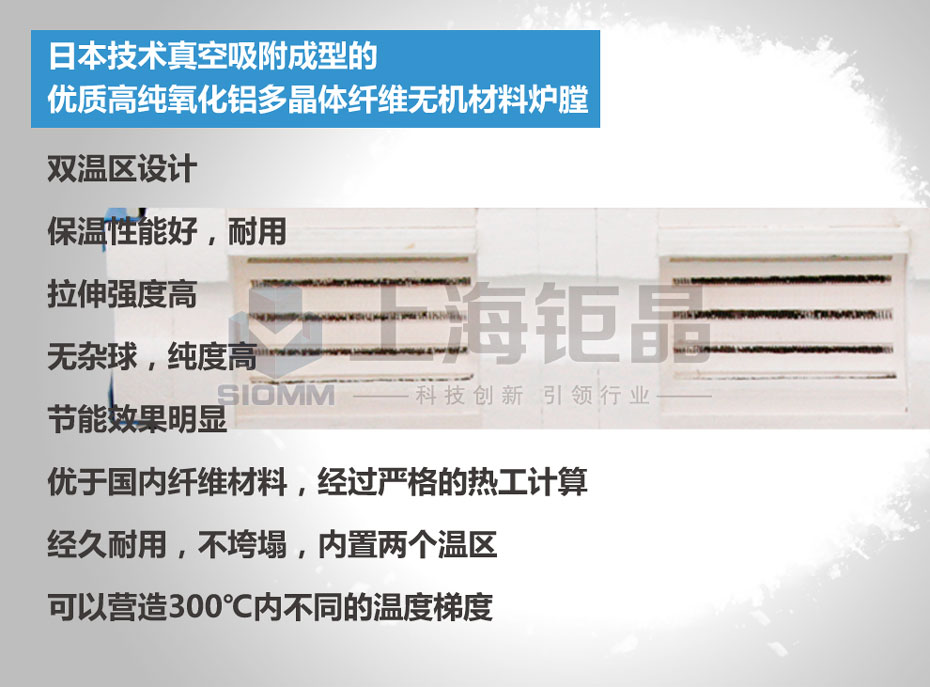

Furnace chamber structure | 1) Double shell with cooling system, ensure furnace surface in low temperature; 2)High pure good quality polycrystalline alumina fiber, good heating preservation; 3) Bottom of furnace installed slidable rail, fast heating and cooling; 4) Open type furnace, can observation the material status in real time |

Power source | AC220V 50/60Hz; 4KW |

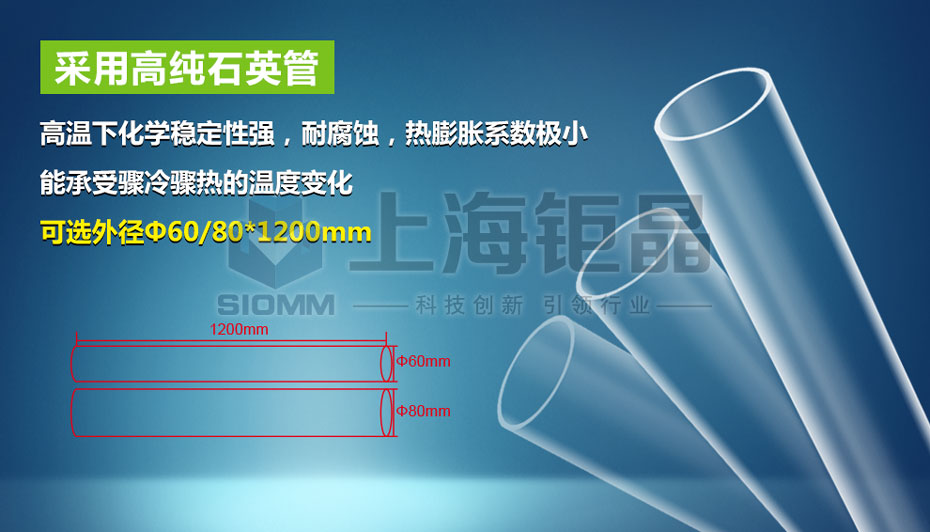

Furnace tube | High pure quartz tube, size: Φ60/Φ80*1200mm |

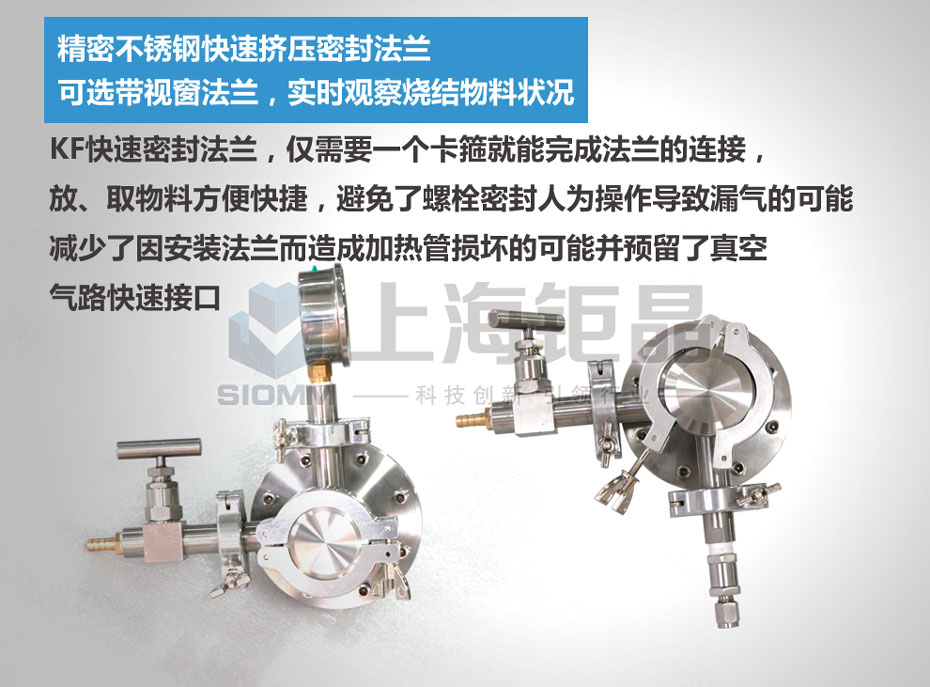

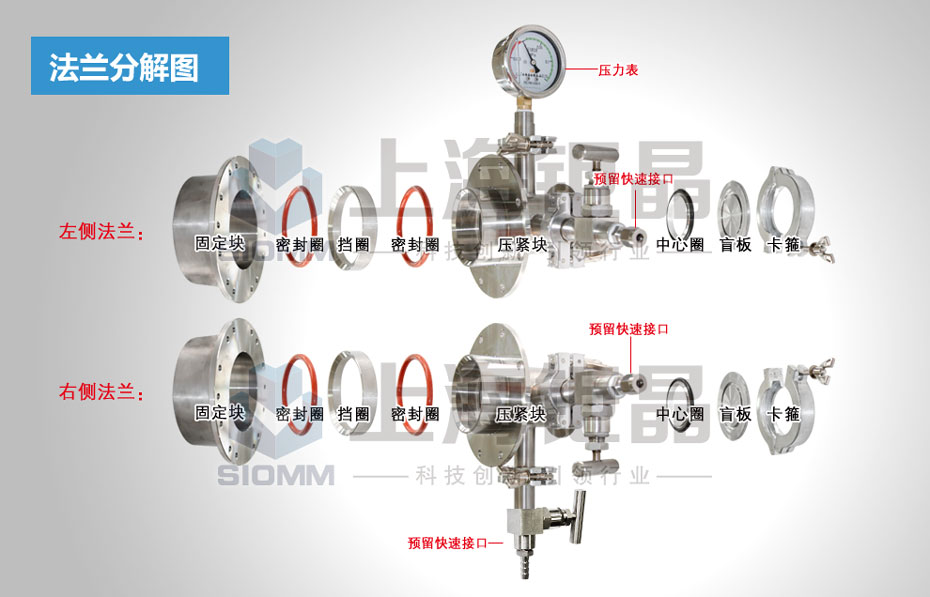

Flange | SUS304 stainless steel KF flange, with ‘o-ring’ seal |

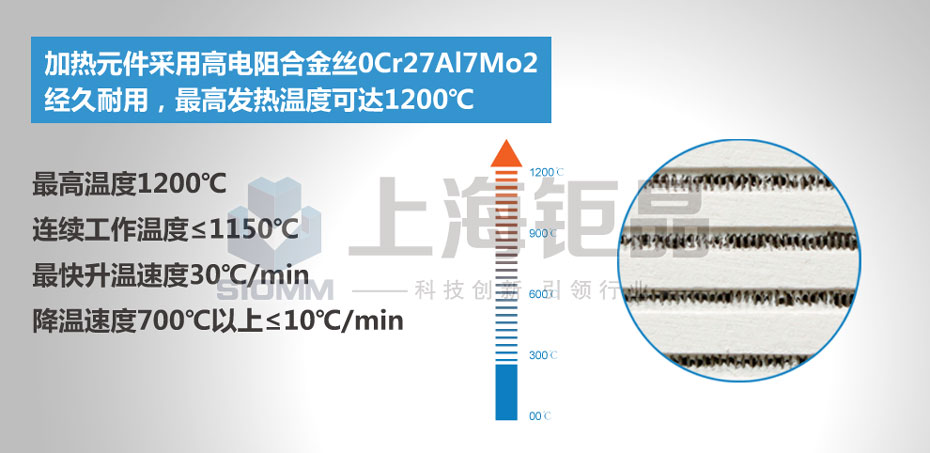

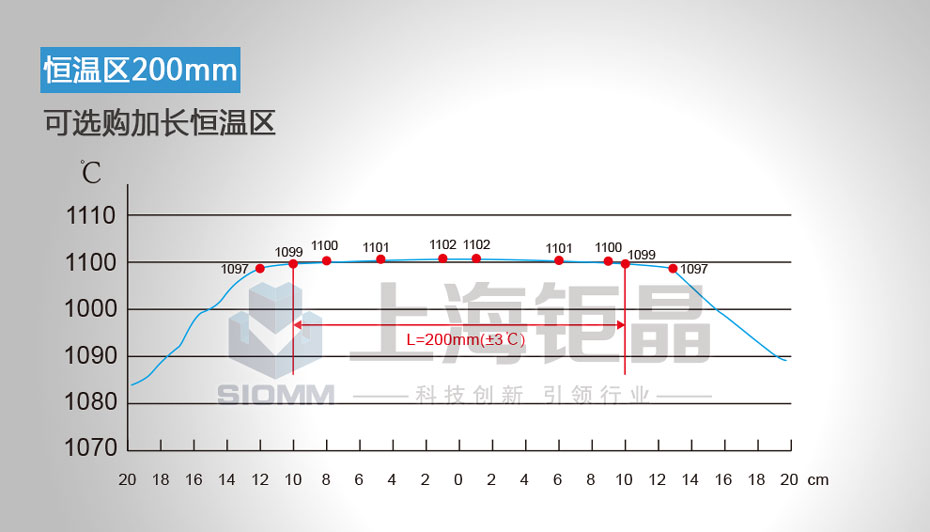

Heating system | 1) High quality resistance wire ( alloy silk 0Cr27Al7Mo2), long time service time; 2) Heating zone length: 410mm 3) Constant heating zone length: 200mm 4) Working temperature: ≤1150℃ 5) Max. temperature: 1200℃ 6) Heating rate: ≤10℃/min (recommend); Max. heating rate: 30℃/min |

Tepm. Control system | 1) Adopted artificial intelligence technology, with PID control, self - tuning function, 30 segments heating and cooling program; 2) Thermocouple: N-type 3) Constant temperature accuracy: ±1℃ |

Gas mixing system | 1) 3 routes gas delivery with mass flow meter: digital display, automatic control gas flow rate; 2) With stainless steel material gas mixing tank, each gas route equipped with check valve; 3) Each input gas route with stainless steel coupling (Ø6) 4) Adjust the button on panel can adjust the gas flow rate; 5) Gas flow range: 0-200sccm 6) Gas flow accuracy: ±1.5%F.S 7) Linear: ±1.5%F.S 8) Repeatability accuracy: ±0.2%F.S 9) Leak rate: 1×10-8 Pa.m3/s 10) Response time: ㄑ8s 11) Max. pressure: 3Mpa 12) Input / output signal: 0 to 5V (Input impedance) |

Vacuum system | 1) High quality mechanical pump, can reach to 0.1Pa; 2) Pumping speed: 4L/s |

Plasma RF Power Supply | 1) Output Power: 5 -500W adjustable with ± 1% stability 2) RF frequency: 13.56 MHz ±0.005% stability 3) Noise: <50 dB. 4) Cooling: Air cooling. 5) Power : 208-240VAC, 50/60Hz |